2026 Top Geomembrane Welding Machine Trends and Innovations?

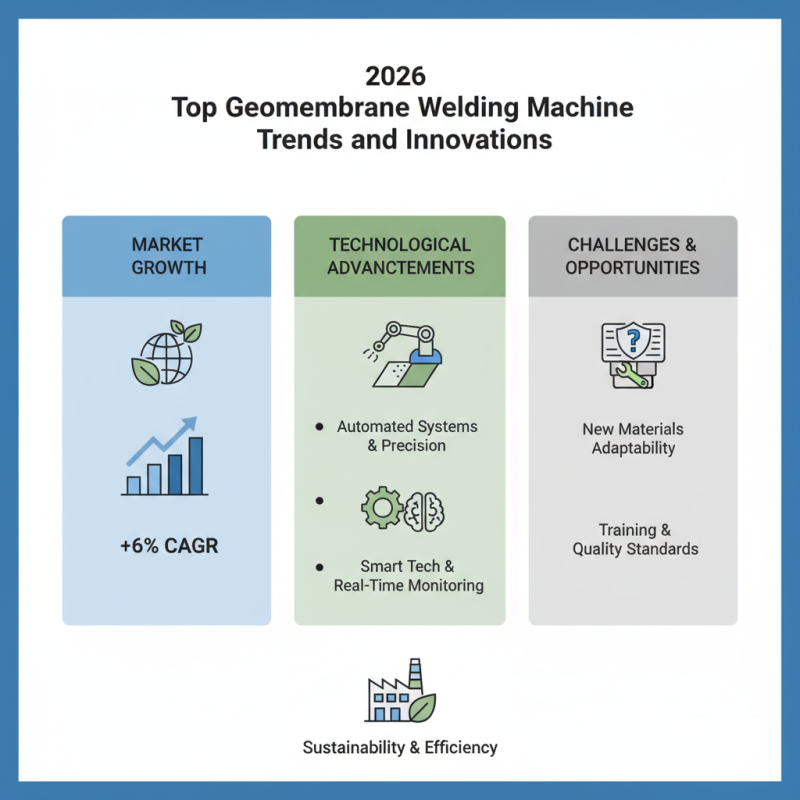

The geomembrane welding machine market is rapidly evolving. Recent reports highlight a projected annual growth rate of over 6% through 2026. This trend reflects increased demand for environmental protection and construction efficiency. As industries prioritize sustainability, innovations in this equipment are essential.

Advances in technology have led to more efficient welding methods. For example, automated systems reduce labor costs and improve precision. Moreover, the integration of smart technology allows for real-time monitoring of weld quality. This shift towards automation underscores the industry's push for higher efficiency.

Yet, there are challenges. Not all machines adapt seamlessly to new materials. Some manufacturers struggle with high-quality standards. Feedback from the field suggests a need for continuous improvement in training and technology. Addressing these issues will be critical as the geomembrane welding machine market continues to expand.

Emerging Technologies in Geomembrane Welding Machines for 2026

Emerging technologies in geomembrane welding machines are set to reshape the industry by 2026. These innovations focus on efficiency, precision, and eco-friendliness. Advanced automation features enhance the welding process, reducing human error. Smart sensors can monitor temperature and pressure in real-time, ensuring optimal weld quality.

One key trend is the integration of energy-efficient designs. Machines now use less power while maintaining high performance. By minimizing energy consumption, companies can reduce costs and environmental impact. Another noteworthy feature is the portability of newer models. Lightweight designs make them easier to transport and use in various locations.

Tips: Regular maintenance is crucial for optimal performance. Dirty parts can lead to unexpected failures. Always check equipment before starting a project. Training operators on new technologies can prevent costly mistakes. Focus on understanding the machine's capabilities.

Connecting with other professionals can spark innovative ideas. Networking helps share best practices and troubleshoot common issues. Experimenting with different techniques can also lead to unexpected improvements. Remember, not every new approach will succeed, but learning from failures is essential.

Key Trends Shaping the Future of Geomembrane Welding Equipment

The geomembrane welding equipment industry is evolving rapidly. Key trends are shaping its future. One major trend is automation. Automated welding machines increase production speed. They reduce human error. This shift can boost efficiency by up to 30%, according to industry reports.

Another important innovation is the use of advanced materials. As projects demand higher durability, suppliers are adopting stronger, more flexible geomembranes. This change allows for better performance. The market sees a rise in demand for materials that can withstand extreme conditions.

Tips: When choosing equipment, consider ease of use. User-friendly machines simplify training for new operators. Regular maintenance is crucial for longevity. Inferior maintenance can lead to increased downtime. Always seek feedback from operators to improve processes. Adaptability will define success in this evolving market.

Innovations in Automation and Robotics for Enhanced Welding Efficiency

The welding industry is evolving rapidly. Innovations in automation and robotics are driving significant changes. These advancements are enhancing welding efficiency for geomembrane applications. According to industry reports, automated welding technologies can improve efficiency by up to 30%. This is crucial for projects requiring precise and durable seams.

Robotic systems have emerged as vital tools in geomembrane welding. They reduce human error and enhance productivity. For instance, machines equipped with laser sensors can ensure accurate seam alignment. The integration of AI can provide real-time data analysis, improving decision-making during the welding process. However, some challenges remain. The high initial investment costs can deter small businesses from adopting these innovations.

Remote monitoring is another key trend. Operators can now supervise welding operations from afar, ensuring quality control. This also creates a need for skilled technicians who can manage these advanced machines. While automation leads to efficiency, it raises questions about workforce skills and training. Balancing technology with human expertise is essential for sustainable progress in the geomembrane industry.

2026 Top Geomembrane Welding Machine Trends and Innovations

| Trend/Innovation | Description | Benefits | Key Features |

|---|---|---|---|

| Robotic Welding Arms | Automation of the welding process using programmable robotic arms. | Increased precision, reduced labor costs, and improved safety. | AI integration, adaptive learning, and precise movement control. |

| Automatic Quality Control Systems | Systems that monitor the welding quality in real-time using sensors. | Higher quality assurance and reduced waste due to early fault detection. | Integrated sensors, data analytics, and feedback loops. |

| Portable Welding Machines | Compact and lightweight welding machines for on-site use. | Increased flexibility and accessibility for diverse project locations. | Battery operation, user-friendly design, and versatile application. |

| Energy-Efficient Welders | Welding machines designed to minimize energy consumption without compromising performance. | Cost savings and reduced environmental impact. | Smart energy management systems and low-power modes. |

| Enhanced Material Compatibility | Machines capable of welding a wider range of geomembrane materials. | Increased versatility and ability to cater to diverse project specifications. | Multi-material feed systems and adjustable welding parameters. |

Sustainability Practices in Geomembrane Welding Machine Design

Sustainability is a pressing concern in the geomembrane welding industry. Over 25% of geomembrane plastic comes from recycled materials. Many companies are exploring eco-friendly alternatives. The focus is on reducing carbon footprints and promoting longer product life cycles. Innovations in machine design aim to enhance energy efficiency. New welding technologies are being developed to minimize waste during the welding process.

Incorporating sustainability practices is not always straightforward. Challenges remain in balancing performance with eco-conscious materials. It requires continuous research and development. Sometimes, the switch to greener options can seem costly. However, long-term savings may outweigh these initial investments. As technology progresses, the cost of sustainable materials is likely to decrease.

Tip: When selecting welding machines, consider their energy consumption. Machines with lower energy use can significantly reduce operational costs.

Additional Tip: Research suppliers who prioritize sustainability in their production methods. Their commitment can reflect positively on your projects. Collaboration with eco-conscious partners enhances overall project integrity.

Market Forecast: Potential Growth and Demand for 2026 Geomembrane Solutions

The geomembrane market is expected to see substantial growth by 2026. A recent report estimates that the global geomembrane market will grow at a CAGR of around 8% from 2021 to 2026. This surge is driven largely by increasing demand in various applications, including water management and waste containment.

Innovations in geomembrane welding machines play a crucial role in this growth. Advanced technologies allow for quicker and more efficient welding processes. These improvements decrease labor costs and enhance the quality of seams. Some manufacturers are focusing on automated welding solutions, which reduce human error. Automation in welding can increase production speed by nearly 30%. However, the initial investment in these machines can be high.

Still, challenges remain. Many companies face difficulties in adopting these new technologies. Training workers to use innovative welding machines is often overlooked. There's also a need for improved quality control during the installation process. As the market evolves, addressing these ongoing challenges will be important to fully capitalize on the potential growth in geomembrane solutions.